Table Of Contents

Poor Installation

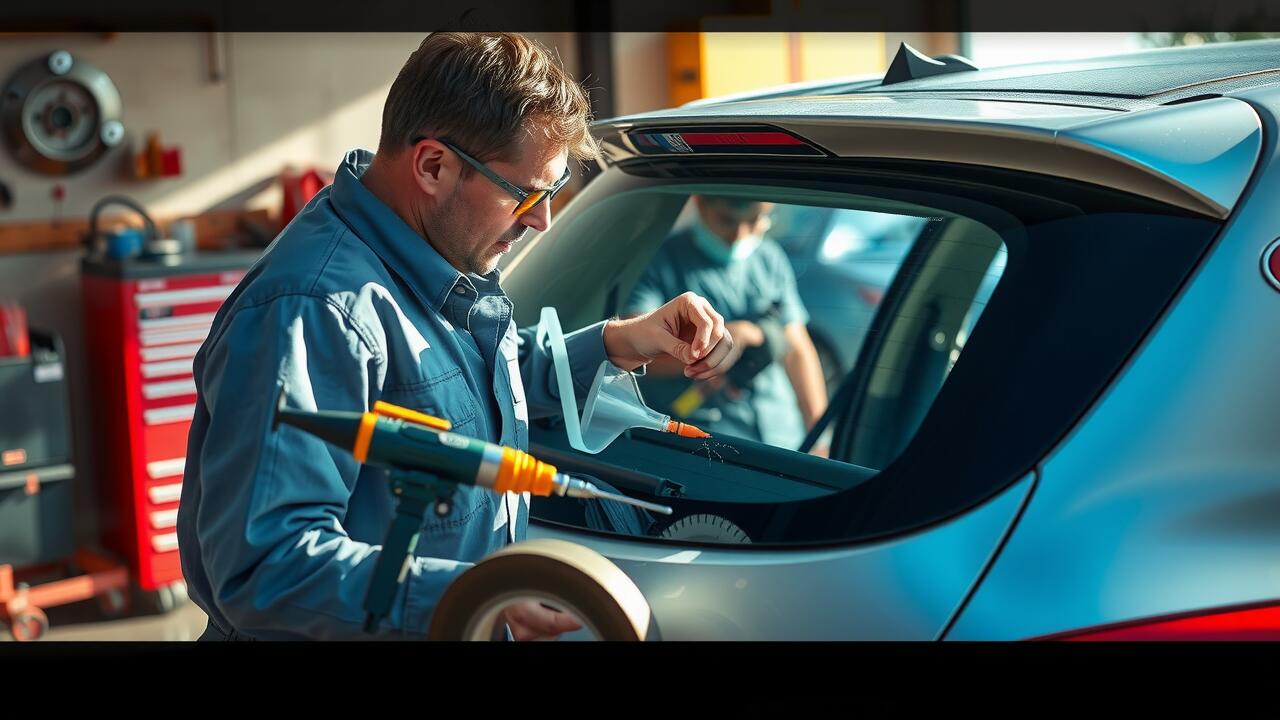

Proper installation of rear window defrosters is crucial for their efficiency and effectiveness. When installation is rushed or performed by inexperienced technicians, misalignments can occur. These errors may lead to areas of the defroster failing to heat properly, which diminishes the overall functionality of the system. Poor alignment of the heating strips can result in cold spots on the glass, making it difficult to clear frost or condensation during cold weather.

In some cases, a poorly installed rear defroster can be exacerbated by other issues, such as a faulty connection in the wiring. If power is not evenly distributed across the heating elements, inconsistencies in heating patterns emerge. This situation can often be further complicated by the need for subsequent repairs, such as side window replacement, which may involve additional costs and time. Ensuring a reliable installation process is essential to avoid these issues from the outset.

Misalignment of Heating Strips

Misalignment of heating strips is a common issue that can significantly affect the efficiency of rear window defrosters. When the heating elements are not properly aligned with the window's contour, they may fail to distribute heat evenly across the surface. This can lead to cold spots that persist even when the defroster is activated, making it difficult to clear fog and ice effectively. In some cases, improper installation during manufacturing or following repairs, such as after a side window replacement, can exacerbate this problem.

Additionally, misalignment may result from the natural wear and tear of the adhesive bonds that hold the strips in place. Over time, the strips may shift due to temperature fluctuations or vibrations while driving. This shifting not only reduces the defroster’s overall effectiveness but can also cause damage to the glass if the heating strips come into contact with it directly. Regular checks after repairs, including side window replacement, can help identify such issues early and ensure optimal functioning of the defroster system.

Temperature Fluctuations

Temperature fluctuations can significantly impact the efficiency of rear window defrosters. When external temperatures change rapidly, it can create stress on the defroster components. This stress may lead to inconsistent heating, making it difficult to clear fog or ice effectively. Such fluctuations often occur during transitional weather, where temperatures hover around freezing.

In some cases, the materials used in the defroster can can lose their effectiveness with changing temperatures. This might result in uneven heat distribution across the rear window. Therefore, a thorough inspection is necessary, especially if there has been a recent side window replacement, to ensure that all elements are functioning properly and no additional issues arise from installation or environmental changes.

Inconsistent Heating Patterns

Inconsistent heating patterns on rear window defrosters can lead to frustration, particularly during winter months when visibility is crucial. This issue often arises when certain sections of the defroster fail to heat evenly, leaving patches of fog or frost on the glass. As temperatures fluctuate, the discrepancies between heated and unheated areas can magnify, making it challenging for the driver to maintain clear sightlines.

Several factors contribute to this problem, including potential damage to the heating strips or electrical connections. A thorough inspection may reveal breakages or wear, necessitating repairs or even partial replacements. In some cases, addressing the defroster's malfunction may involve considering additional services such as Side Window Replacement to ensure overall clarity and safety while driving.

Wear and Tear Over Time

As rear window defrosters age, they are subject to wear and tear that can significantly affect performance. The heating elements can become damaged due to prolonged exposure to temperature fluctuations. This deterioration can result in uneven heating patterns, leaving parts of the glass still foggy or icy. Regular maintenance checks can help identify these issues early, potentially saving on larger repairs later.

In some cases, the wiring and connections responsible for powering the defroster may also corrode over time. This can lead to intermittent functioning or complete failure of the defroster system. Drivers might find themselves facing the need for repairs or even a side window replacement if damage spreads beyond the defroster's components. Addressing these issues promptly helps ensure optimal visibility and safety on the road.

Deterioration of Components

As with many components in a vehicle, rear window defrosters experience wear and tear over time. Factors such as exposure to sunlight and temperature changes contribute to the deterioration of the heating elements. This decline often results in reduced effectiveness, with certain sections of the defroster becoming sluggish or completely inoperative. Regular inspections can help identify these issues before they worsen.

Another aspect of deterioration involves the connections and circuitry that power the defroster. Corrosion or damage to these components can disrupt functionality, leading to inconsistent heating patterns across the glass. In cases of severe failure, a side window replacement may be necessary to restore optimal visibility and safety for drivers and passengers alike.

FAQS

What are the most common problems with rear window defrosters?

The most common problems include poor installation, misalignment of heating strips, temperature fluctuations, inconsistent heating patterns, and wear and tear over time.

How can poor installation affect my rear window defroster?

Poor installation can lead to misalignment of heating strips, which may cause uneven heating and inefficient defrosting, resulting in foggy or icy windows.

What causes temperature fluctuations in rear window defrosters?

Temperature fluctuations can be caused by electrical issues, faulty wiring, or a malfunctioning thermostat, preventing the defroster from heating consistently.

How do I know if my rear window defroster has inconsistent heating patterns?

If you notice that certain areas of your rear window remain foggy or icy while others are clear, it may indicate inconsistent heating patterns in your defroster.

What signs indicate wear and tear on my rear window defroster components?

Signs of wear and tear can include visible damage to the heating strips, reduced effectiveness in defrosting, or a complete failure of the defroster to operate.