Table Of Contents

Windshield Repair Kits

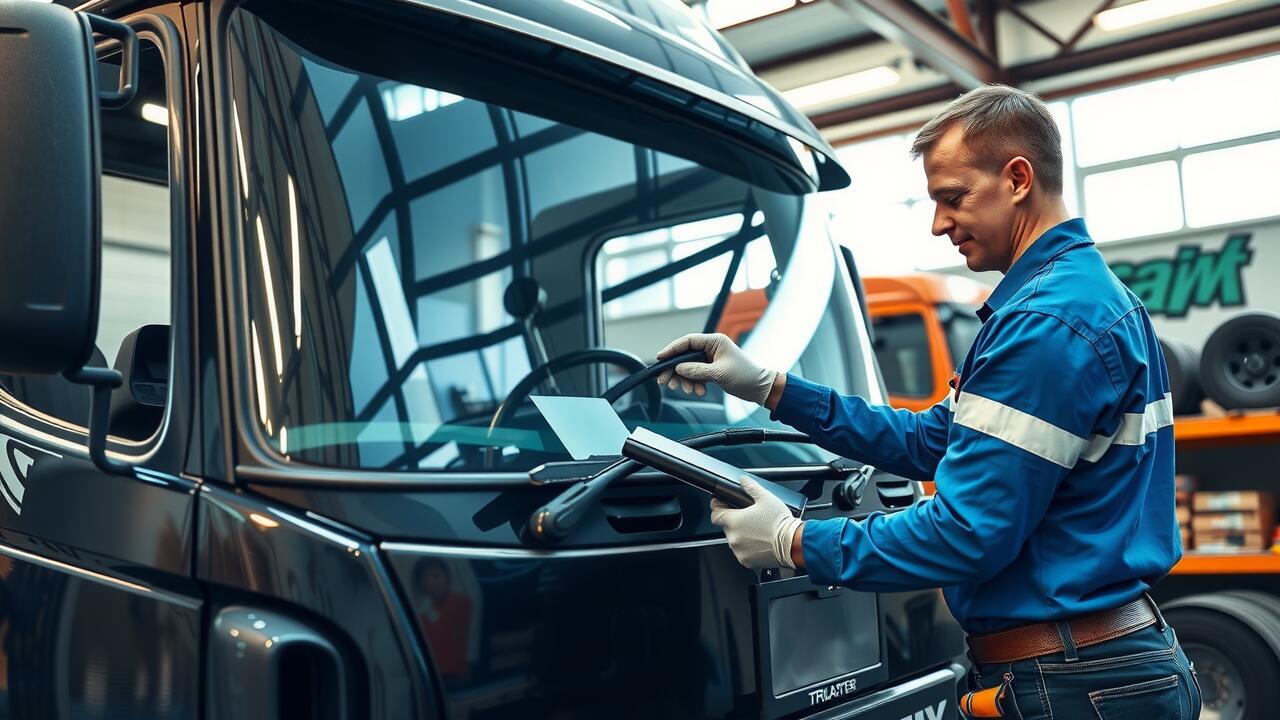

Windshield repair kits offer a convenient solution for addressing minor chips and cracks in glass. These kits generally come equipped with various tools and materials designed for effective repair without requiring professional assistance. The components often include a resin injector, repair resin, and curing film, suitable for a variety of damage types. Using a repair kit can save time and money while ensuring the vehicle's visibility and structural integrity remain intact.

For those considering home repairs, searching for "truck windscreen repairs near me" can yield local professionals who can provide guidance or alternative options. While DIY kits can be effective, some damage may necessitate expert intervention to ensure a safe and long-lasting repair. Knowledge of what a repair kit includes can empower vehicle owners to make informed decisions, balancing the convenience of self-repair with the reassurance that comes from professional support.

Components Typically Found in Repair Kits

Repair kits for truck windscreens typically contain several essential components designed to effectively address chips and cracks. A resin injector is a common tool, allowing for precise application of the resin into damaged areas. The resin itself is a crucial material known for its ability to bond well and restore structural integrity. Additionally, many kits include a curing light to speed up the hardening process, ensuring a swift and durable repair.

Alongside the resin injector and curing light, repair kits often feature blades for cleaning and preparation of the damaged area. This step is vital, as a clean surface enhances the adhesion of the repair resin. Some kits may also come with instructional manuals or videos for users seeking guidance on performing repairs independently. For those searching for assistance, "truck windscreen repairs near me" can help locate professional services that ensure a comprehensive fix.

Safety Glass Specifications

Safety glass is designed to minimise the risk of injury during accidents by shattering into small, blunt pieces rather than sharp shards. This feature is crucial for the protection of both the driver and passengers. When considering truck windscreen repairs near me, it is important to ensure that the replacement glass meets Australian safety standards. These standards stipulate that glass used in vehicles must adhere to specific regulations regarding strength and impact resistance.

There are two primary types of safety glass commonly used in vehicles: laminated and toughened. Laminated glass consists of two layers of glass with a plastic interlayer, providing excellent protection against impacts while retaining structural integrity. Toughened glass is heated and rapidly cooled, making it significantly stronger than standard glass. Understanding these specifications can aid in selecting the appropriate material for truck windscreen repairs near me, ensuring both safety and durability for vehicles on the road.

Understanding Laminated versus Toughened Glass

Laminated glass consists of two or more layers of glass that are bonded together with a plastic interlayer, typically made of polyvinyl butyral (PVB). This structure not only enhances safety by holding shattered glass fragments in place but also provides superior acoustic insulation. In the event of a break, the interlayer helps to prevent glass shards from causing injury, making laminated glass a popular choice for truck windscreens where visibility and protection are paramount. For those seeking truck windscreen repairs near me, laminated options are often recommended for their durability and safety features.

Toughened glass, or tempered glass, undergoes a heat treatment process that makes it significantly stronger than regular glass. When broken, toughened glass shatters into small, blunt pieces that are less likely to cause injury. While toughened glass is commonly used in various automotive applications, it lacks the same protective qualities against impact as laminated glass. For truck windscreen repairs, understanding the differences between these types of glass can help vehicle owners make informed decisions about safety and the suitability of materials for their specific needs.

Environmental Considerations

Environmental considerations play a crucial role in the materials used for truck windscreen repairs. The industry is increasingly recognising the importance of utilising eco-friendly products and processes. Many repair kits now incorporate adhesives and resins that are designed to be more environmentally friendly, reducing harmful emissions and the overall ecological footprint. Using sustainable materials can also contribute to less waste in landfills as these products often have longer life spans and lower toxicity levels.

When searching for "truck windscreen repairs near me," it helps to consider establishments that prioritise sustainable practices. Look for services that offer recycled glass options or utilise cutting-edge techniques that minimise waste. By choosing eco-conscious companies, vehicle owners can ensure that their repairs not only restore functionality to their trucks but also align with a commitment to environmental responsibility. This approach reflects a broader movement towards sustainability within the automotive industry, benefiting both consumers and the planet.

Eco-Friendly Materials for Windscreen Repair

In recent years, there has been a growing emphasis on eco-friendly materials in the automotive repair industry, including windscreen repairs. Many products are now formulated with sustainable resources, reducing the environmental impact associated with traditional materials. For instance, some repair resins are made from plant-based ingredients, which not only enhances their eco-friendliness but also offers effective performance in sealing cracks.

When searching for "truck windscreen repairs near me," one can find service providers that prioritise the use of these environmentally conscious materials. By opting for businesses that utilise sustainable repair solutions, vehicle owners can contribute to reducing waste and promoting greener practices within the automotive sector. This shift not only benefits the environment but also aligns with the growing consumer demand for responsible repair options.

FAQS

What are the main components of a truck windscreen repair kit?

A typical truck windscreen repair kit includes resin, a curing agent, a syringe or injector, a blade for cleaning, and sometimes a special adhesive tape to fix the repair process in place.

How is laminated glass different from toughened glass in windscreen repairs?

Laminated glass consists of two layers of glass with a layer of vinyl in between, providing added safety and preventing shattering. Toughened glass, on the other hand, is heat-treated to increase strength but shatters into small pieces when broken, which can complicate repairs.

Are there eco-friendly materials used in truck windscreen repair?

Yes, many manufacturers now offer eco-friendly resins and adhesives that are less harmful to the environment, minimising the impact of windscreen repairs on our planet.

How does the type of glass affect the repair process?

The type of glass influences the repair methods and materials used; for instance, laminated glass may require specific resins and techniques to ensure a proper seal and maintain structural integrity.

Is it possible to repair a windscreen with a large crack?

In general, windscreen repairs are most effective for small chips and cracks. If a crack is larger than a certain length or in the driver's line of sight, replacement may be necessary for safety reasons.