Table Of Contents

Common Mistakes to Avoid

One of the most common mistakes made during windscreen repairs is the improper selection of adhesive. Choosing the wrong type can compromise the integrity of the repair, leading to further damage or even injury. Many individuals opt for general-purpose adhesives, unaware that specific formulations are designed to withstand the unique stresses placed on a windscreen. In truck windscreen repairs, for example, the adhesive must cater to the additional weight and vibrations experienced due to larger vehicle dynamics.

Another frequent error involves the incorrect application technique of adhesives. This includes not applying the adhesive evenly or failing to allow for adequate curing time before the vehicle is put back into service. Such oversights can result in weak bonds that fail under pressure. In truck windscreen repairs, this can pose serious safety risks. Ensuring precise application and curing conditions is vital to maintaining the windscreen's structural integrity.

Misapplication of Adhesives and Their Consequences

Misapplication of adhesives can have significant consequences, especially in critical situations like truck windscreen repairs. If the adhesive is not applied correctly, it can lead to improper bonding, resulting in leaks or even the windscreen detaching while driving. This not only poses a safety risk to the driver and passengers but can also lead to costly damage to the vehicle. Furthermore, using the wrong type of adhesive can deteriorate the integrity of the windscreen over time, potentially leading to more serious issues down the line.

Inadequate application techniques may also affect the warranty of the windscreen or the vehicle itself. If a repair fails, insurance claims may be denied based on improper methods used during the fixing process. The repercussions of misapplied adhesives in truck windscreen repairs extend beyond immediate safety concerns, impacting long-term vehicle maintenance and repair costs. Ensuring the right adhesive is used and applied by a professional is crucial to avoid these pitfalls and preserve the vehicle's functionality.

Benefits of Professional Windscreen Repair

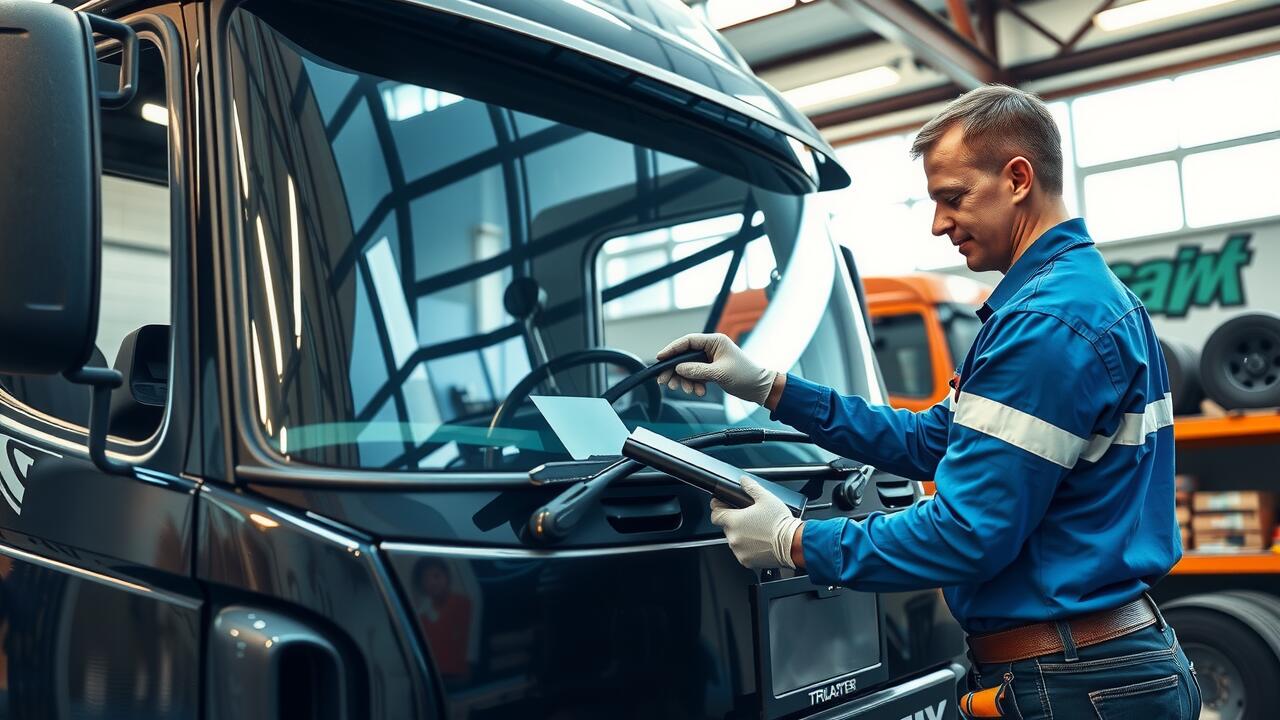

Professional windscreen repair ensures a higher standard of workmanship and material quality compared to DIY attempts. Technicians possess the necessary training and experience to assess damage accurately and select the appropriate adhesives for various types of repairs. This expertise eliminates the risks commonly associated with improper application, which can lead to further complications down the line. Professionals can also recognise underlying issues that may not be immediately visible, ensuring a comprehensive repair.

For those requiring truck windscreen repairs, the benefits become even more pronounced. Large vehicles demand specific adhesive solutions to account for their additional weight and stresses. A skilled technician understands these nuances, ensuring the integrity of the repair and the safety of the vehicle. Moreover, using a professional service often comes with warranties, providing peace of mind that the repairs will hold up over time. This reassurance can ultimately save money, as well-maintained windscreens reduce the likelihood of needing further repairs or replacements.

Why Expertise Matters in Adhesive Application

The application of adhesives in windscreen repairs demands a level of expertise that is critical to ensuring both safety and longevity. Professionals understand the specific requirements of different adhesives, including curing times and environmental factors that can affect their performance. This knowledge is particularly essential for complex scenarios like truck windscreen repairs, where larger glass surfaces and structural considerations come into play. An informed application can prevent issues such as improper bonding, which may lead to further damage or failure of the windscreen.

Technicians trained in adhesive application are also familiar with the tools and procedures necessary for optimal results. Their expertise helps to avoid common pitfalls, such as using the wrong adhesive type or applying it in inappropriate conditions. In truck windscreen repairs, even minor miscalculations can compromise the vehicle's structural integrity and the safety of its occupants. Trusting a skilled professional for these repairs not only enhances the effectiveness of the adhesive but also ensures compliance with safety regulations, ultimately providing peace of mind to vehicle owners.

Cost Implications of Using Incorrect Adhesives

Using incorrect adhesives in truck windscreen repairs can lead to significant cost ramifications over time. The initial saving gained from opting for a cheaper adhesive may quickly vanish when the repair fails. A compromised bond can cause additional damage, necessitating a complete replacement of the windscreen, which is far more expensive than a professional repair from the outset.

Moreover, the financial implications extend beyond immediate costs. Insurers may impose higher premiums for poorly executed repairs, perceiving them as a risk. Customers might also incur more frequent maintenance fees due to recurrent issues from substandard adhesive application. Thus, investing in the right adhesive plays a critical role in minimising overall expenditure.

Long-term Savings Through Proper Repair

Investing in the correct adhesives for truck windscreen repairs can yield significant long-term savings. When adhesives designed specifically for automotive applications are applied correctly, they enhance the structural integrity of the windscreen. This not only ensures the safety of the vehicle occupants but also reduces the likelihood of future repairs. By addressing the problem effectively the first time, both time and money are saved on repeat visits to repair shops.

Choosing cheaper or incorrect adhesives may initially appear cost-effective. However, the risk of failure increases, potentially leading to more severe issues down the line. This could result in additional repairs or even complete replacements of the windscreen, which are often much pricier and more time-consuming. Ensuring proper application with the right materials transforms what may seem like a minor investment into a significant financial advantage over time.

FAQS

Why is it important to use the correct adhesive for windscreen repairs?

Using the correct adhesive is crucial for ensuring the structural integrity and safety of the windscreen. It helps to maintain the bond between the glass and the frame, preventing leaks and potential accidents.

What are some common mistakes people make when applying adhesives in windscreen repairs?

Common mistakes include misapplying the adhesive, using products that are not suited for automotive glass, and failing to properly prepare the surfaces before application, which can lead to inadequate bonding and compromised safety.

How can professional windscreen repair services benefit me?

Professional services ensure that the right adhesive is used and applied correctly, which can enhance the longevity of the repair, ensure safety, and save you from costly mistakes associated with DIY repairs.

What are the cost implications of using the wrong adhesive in windscreen repairs?

Using the wrong adhesive can lead to further damage, requiring additional repairs or even a complete windscreen replacement, which can significantly increase overall costs.

How can proper adhesive application lead to long-term savings?

Proper adhesive application ensures a durable bond that can withstand environmental stresses, reducing the likelihood of needing future repairs or replacements, thus saving you money in the long run.