Table Of Contents

The Tools Needed for Effective Windscreen Installation

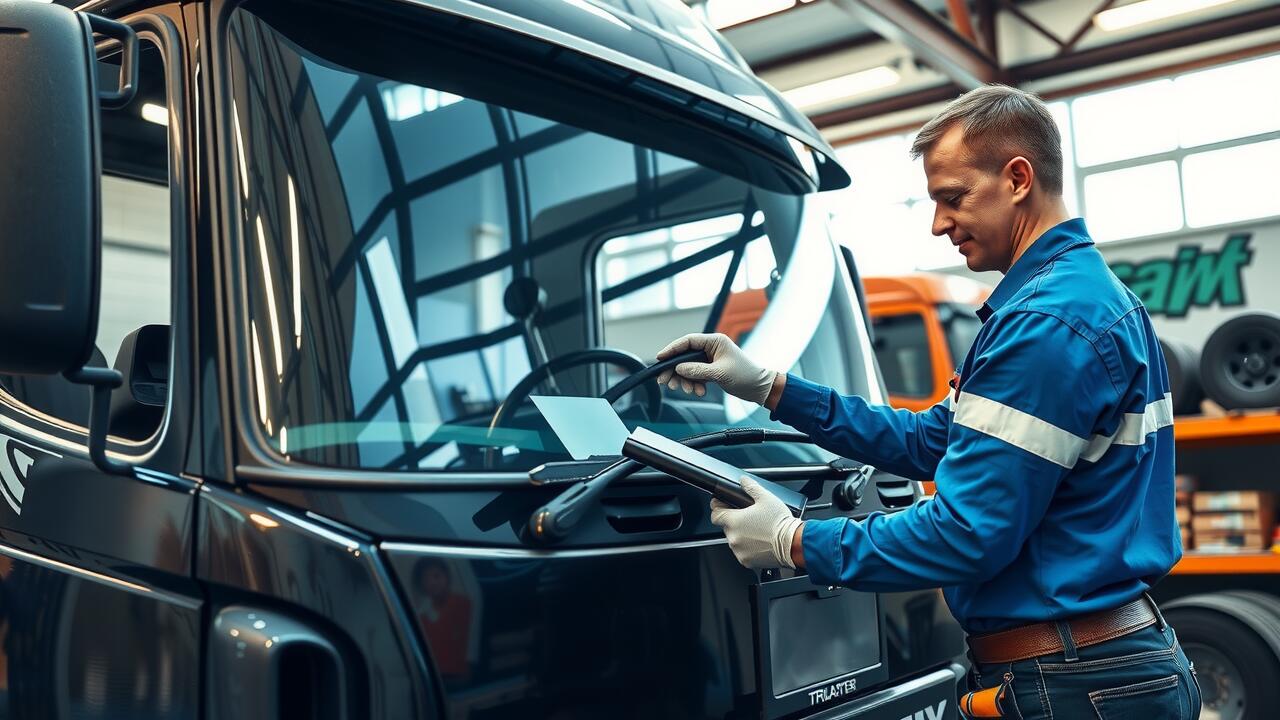

Having the right tools is essential for effective truck windscreen repairs. Each piece of equipment plays a vital role in ensuring a secure and seamless fit. Basic tools include a suction cup and a windscreen knife for precise glass removal. Additionally, a sealant gun for applying adhesive and a heater to assist with curing the sealant can make a significant difference in the overall quality of the installation process.

Specialised tools like a wet cut saw or a urethane removal tool can also enhance efficiency and accuracy. These tools allow for cleaner cuts and easier removal of old glass, which is crucial to avoid compromising the integrity of the new windscreen. Investing in quality equipment for truck windscreen repairs can ultimately save time and resources while ensuring safety for both the vehicle and its occupants.

Essential Equipment for Professional Repairs

When it comes to truck windscreen repairs, having the right tools is essential for achieving optimal results. A high-quality adhesive applicator ensures a seamless bond between the windscreen and the truck frame. This tool allows for precise application, minimising the risk of air bubbles or gaps that may lead to leaks or reduced structural integrity. Additionally, a suction cup tool is vital for safely manipulating and positioning the windscreen during installation, reducing the risk of damage to both the glass and surrounding components.

Moreover, a professional-grade glass cutter is necessary for precision when handling replacement glass. It provides clean, accurate edges that fit snugly into the frame, ensuring a proper seal. A set of safety gloves and goggles is also crucial to protect technicians while working with glass. These essentials not only improve the efficiency of the process but significantly enhance the safety and durability of truck windscreen repairs, positioning professionals for successful outcomes.

Recognising Signs of Improper Installation

Recognising signs of improper installation is crucial for maintaining the integrity of your vehicle. A poorly installed truck windscreen may exhibit visible gaps between the glass and the frame. These spaces can allow moisture to enter, leading to potential corrosion or mould issues within the cabin. Additionally, an uneven fit may create noise while driving, indicating that the windscreen is not securely in place.

Other warning signs include the presence of air bubbles or distortion in the glass itself. If the visibility is compromised while driving, this can significantly impact safety. It's important to inspect the adhesive used for the installation as well. If it appears to be peeling or insufficient, the effectiveness of truck windscreen repairs could be at risk, necessitating immediate attention from a professional.

Symptoms That Indicate a Faulty Windscreen

A faulty truck windscreen can manifest through various symptoms that should not be ignored. One common indicator is the presence of leaks, which can allow water to penetrate, causing damage to the vehicle's interior and electronics. Additionally, a misaligned windscreen might create visibility issues, compromising safety during driving. Such signs, when overlooked, can lead to more significant problems down the line.

Another symptom of improper installation is the appearance of air or wind noise while driving. This is often a result of a poor seal, which not only disrupts a comfortable ride but can also signal that the windscreen is not securely fixed. Furthermore, visible gaps between the windscreen and truck body may also be apparent. Addressing these issues promptly through professional truck windscreen repairs can prevent further complications and ensure the vehicle's integrity.

Professional vs. DIY Windscreen Repairs

When considering truck windscreen repairs, opting for professional assistance often brings peace of mind. Professionals come equipped with the right tools and experience, ensuring that every step of the repair process adheres to safety standards. Their expertise minimises the risk of complications that could arise from improper installation, which can lead to further damage or costly mistakes.

On the other hand, DIY options can be appealing for those seeking to save money. However, without the necessary skills and equipment, the chances of making errors increase significantly. Attempting truck windscreen repairs without adequate knowledge may result in poorly fitted glass that could jeopardise safety on the road. Thus, weighing the potential risks against the savings is crucial before deciding on a DIY route.

Weighing the Benefits of Hiring Experts

Hiring experts for truck windscreen repairs brings a level of assurance that can be hard to achieve through do-it-yourself methods. Professionals have extensive experience in the field, allowing them to identify issues quickly and provide effective solutions. They also have access to high-quality materials and equipment, ensuring that the repair is durable and meets safety standards.

Moreover, professional services often come with warranties or guarantees that can give truck owners peace of mind. In the event of a mistake or malfunction, expert repairers can address the problem without additional costs. This safety net is crucial, especially given the risks associated with improper installation, which can lead to significant hazards while driving.

FAQS

Why is proper installation important for truck windscreen repairs?

Proper installation is crucial as it ensures the windscreen is securely fitted, providing structural integrity to the vehicle, preventing leaks, and maintaining visibility. Improper installation can lead to further damage and safety hazards.

What tools are essential for effective windscreen installation?

Essential tools for effective windscreen installation include a glass suction cup, a sealant gun, a utility knife, and a scraper. These tools help ensure precision and adherence during the installation process.

How can I recognise signs of improper windscreen installation?

Signs of improper installation can include water leaks, wind noise, visible gaps between the windscreen and frame, and the glass not sitting flush with the vehicle body. If you notice any of these issues, it may indicate a faulty installation.

Is it better to hire a professional for windscreen repairs or attempt a DIY fix?

While DIY repairs may seem cost-effective, hiring a professional is often better as they possess the expertise, experience, and tools needed to ensure a proper installation, which can prevent future complications.

What are the potential consequences of a faulty windscreen installation?

A faulty installation can lead to serious consequences, including compromised vehicle safety, increased risk of injuries during accidents, and expensive repairs if the windscreen needs to be replaced again.